430 2205 204 304 304l 316l 202 201 6Mm Stainless Steel 1.4372 2Mm

12Cr17Mn6Ni5N Metal Plate

Stainless Steel Plate

Stainless steel is a versatile stainless steel that is widely used

in the production of equipment and parts that require good

comprehensive performance (corrosion resistance and molding).In

order to maintain the corrosion resistance inherent in stainless

steel, stainless steel plate must contain more than 18% chromium

and more than 8% nickel content.

Advantages of our stainless steel Plate:

1. Wide Specifications Range;

2. Pure steel chemical composition;

3. Outstanding mechanical properties;

4. Good performance after welding;

5. Good shape and high precision;

6. Excellent corrosion-resistant and long service life.

Specifications:

| | | | |

| | T*1220mm T*1800mm T*2000mm 1.0mm*1500mm |

| | | | |

| | | | |

| | 4.0*1500mm 5.0*1500mm 6.0*1500mm |

| | | | |

| | |

| | |

| | 304 / 321 / 316L / 2205 / 235MN / 347H / 2520 / 2507 / 317L / 309S / 310S / 904L |

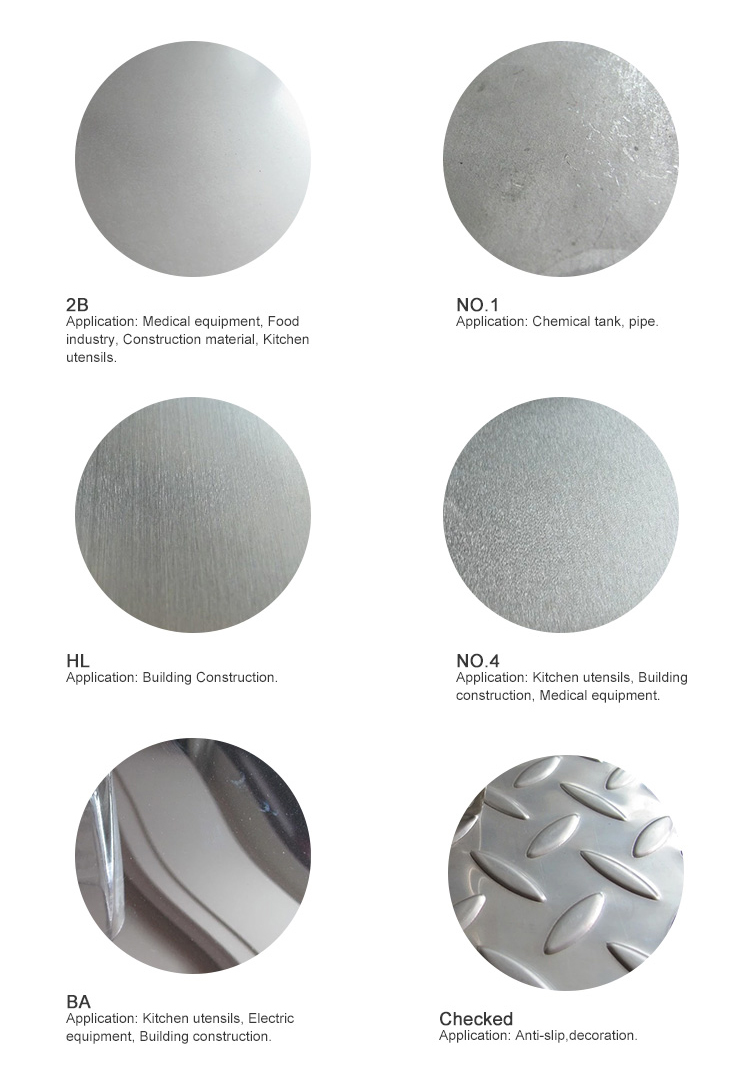

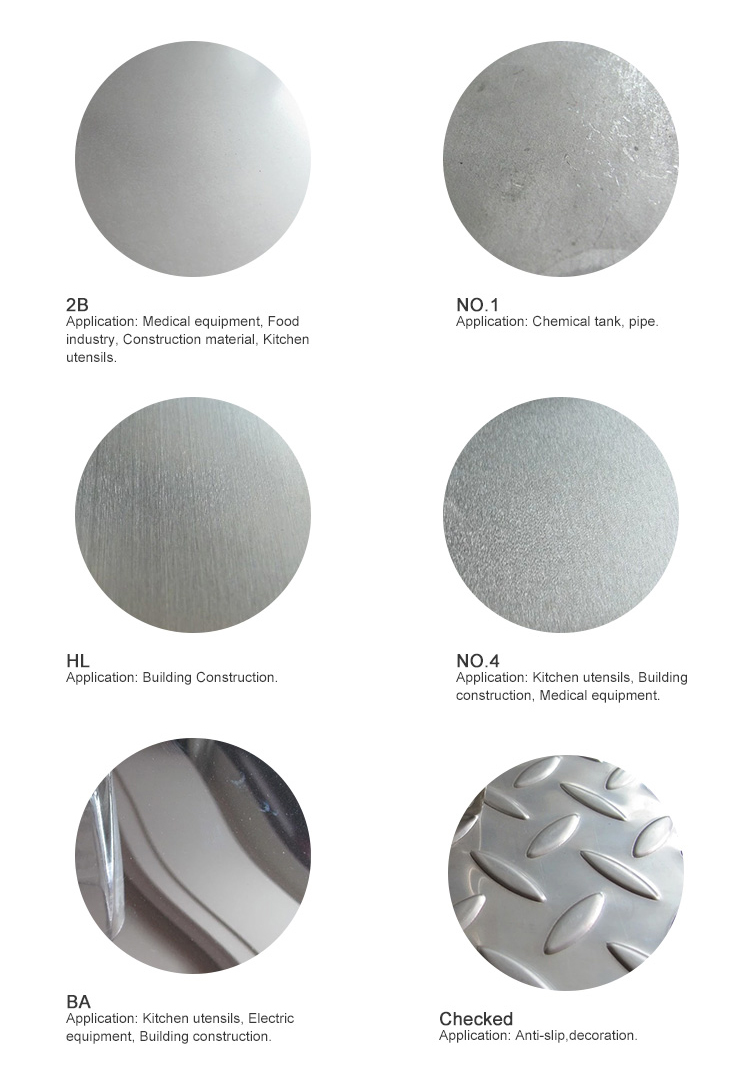

| No.1, 2D, 2B, BA, No.3, No.4, No.240, No.320, No.400, HL, No.7,

No.8,Embossed |

Surface

| | Surface finishing methods | |

| | Heat treatment after hot rolling,pickling,or with treatment | For without the purpose of the surface gloss |

| | Method of heat treatment after cold rolling,pickling surface roller

with wool or eventually a light rolling a matte surface processing | General materials,building materials |

| | Giving NO.2 processing materials appropriate method of cold light

sheen | General materials,building materials(most of the goods are

processed |

| | Bright heat treatment after cold rolling,in order to be more

shingy,cold light effect | Automaotive parts,home appliances,vehicles,medical equipment,food

equipment |

| Shiny,coarse grain processing | The NO.2D or NO.2B processing timber NO.100-120 polishing abrasive

grindding belt | Building materials,ketchen supplies |

| | The NO.2D or NO.2B processing timber NO.150-180 polishing abrasive

grindding belt | Building materials,ketchen supplies,vehicles,medicals |

| | The NO.2D or NO.2B processing timber 240 polishing abrasive

grindding belt | |

| | The MO.2B timber 400 polishing wheel polishing method | Building materials,kitchen utensils |

| Polishing line having a long continuous processing | In a suitable size(usually mostly No.150-240 grit)abrasive tape for

as long as the hair,having a continuous processing methond of polishing line. | The most common building materials processing |

| NO.4 processing less than the reflection ,the extinction | NO.4 processing material used for polishing Tampico brushing | Building materials ,decorative |

| Highly accurate reflectance mirror processing | NO.600 of the totary buff with a polishing | Building materials ,decorative |

| highest relfectivity mirror finish | Fine particles of abrasive material in order polishing,mirror

polishing with a polishing | Building materials ,decorative,mirrors |

Application

1: Chemical industry: Equipment, industrial tanks and etc.

2: Medical instruments: Surgical instruments, surgical implants and

etc.

3: Architectural purpose: Cladding, handrails, elevator,

escalators, door and window fittings, street furniture, structural

sections, enforcement bar, lighting columns, lintels, masonry

supports, interior exterior decoration for building, milk or food

processing facilities and etc.

4: Transportation: Exhaust system, car trim/grilles, road tankers,

ship containers, refuse vehicles and etc.

5: Kitchen Ware: Tableware, kitchen utensil, kitchen ware, kitchen

wall, food trucks, freezers and etc.

6: Oil and Gas: Platform accommodation, cable trays, sub-sea

pipelines and etc.

7: Food and Drink: Catering equipment, brewing, distilling, food

processing and etc.

8: Water: Water and sewage treatment, water tubing, hot water tanks

and etc.

And other related industry or construction field.

Packing & Shipping

With all kinds of processing, NC flame, plasma, laser and water jet

cutting, drilling, punching,welding, bending, etc.

hot rolled mirror finished 400 series stainless steel plate

We can also provide you with the following services:

1. Unscreen-rolling of steel coils and flattening into steel plates

2. Steel coil is divided into strip and steel strip.

3, split into small steel coil

Related production:

(1)Cold rolled steel coils cut to plate

Thickness: 0.5mm-3.0mm width: 800mm/1250mm

(2)Galvanized steel plate

Galvanized steel coils cut to plate

Thickness: 0.1mm-2.5mm width: 600mm/800mm/1250mm

(3) Al-zinc coils and plate

(4)Seamless steel pipe, seamless steel tube, seamless pipe, Hollow

bar sizes: outer diameter: 8mm-800mm, wall thickness: 1mm-80mm

(5) Round bar

Material: S235JR, 1045, 1018, 1518, 1020, 41040, 4340, 8620 and

other materials

Diameters: 3mm- 800mm

(6)Steel profile

Angle bar; channel bar; h beam; rectangular tubes, u tube, H beam,

flat bar, and so on.